MACHINE POLISHING

DA POWER SYSTEM

The DA Power System is a drill mounted tool that bridges the gap between hand and machine polishing. The DA power system works with your corded drill to quickly and effectively remove light to moderate defects such as swirls, oxidation and stains and to apply polishes and waxes.

To use the DA Power System, insert the power system into the drill and tighten securely.

For buffing using moderate downward pressure, in an overlapping pattern while keeping the pad flat against the paint at all times. Ensure that the pad is perpendicular to the surface to ensure even coverage. Work a small section at a time, applying additional product as needed until all defects have been removed.

Attach the pad to the Power System and apply Ultimate Compound directly to the pad.

Then place the pad flat against the paint and begin buffing using moderate downward pressure, in an overlapping pattern while keeping the pad flat against the paint at all times.

Ensure that the pad is perpendicular to the surface to ensure even coverage. Work a small section at a time, applying additional product as needed until all defects have been removed.

Tip: Remove any product residue with a Meguiar’s Microfibre towel, prior to applying any polishes or waxes.

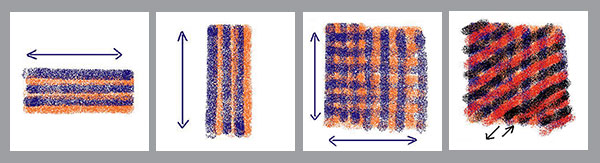

The following diagrams indicate the best application movements using your Meguiar’s Dual Action Polisher & DA Power System.

- Start working the product in overlapping horizontal movements.

- Continue the overlapping in a vertical direction.

- After completing steps 1 & 2 the panel should resemble the grid above.

- A third application will go even further to ensure fuller defect removal.

DA POLISHER

Whether you’re a seasoned professional or casual user who wants to achieve, quality, swirl- free results, this is the tool for you.

The Meguiar’s Dual Action Polisher greatly reduces the amount of time it takes to apply paint cleaners, polishes and protection products and produces results far superior to applying these products by hand. And because of its dual action – rotatory and orbital, you never have to worry about burning the paint.

It is important to remember that to completely remove a scratch, the clear coat must be cut back to the lowest level of the scratch. It is sometimes the case that the much deeper defects can only be removed by a rotary machine or by re-painting.

Ensure that the vehicle is thoroughly washed and dried before attempting to machine polish. If there are above surface contaminants, remove them with the Clay Detailing systems described in the surface preparation section. This will ensure that the paint can be correctly assessed, and as a result the correct product can be chosen.

Before the application of product to the pad, apply a small amount of Quik Detailer to “prime” the pad. Then apply Ultimate Compound or SwirlX to the foam polishing pad in an X shape.

The machine should always be started and stopped whilst against paintwork, this will avoid product splatter.

It is best to work on small areas rather than trying to tackle the whole vehicle in one go. Work an area approximately 50cm X 50cm and use slow overlapping movements, until the product has turned to a haze.

There is no need to apply any pressure to the head of the machine, just use the handle to guide and steady the Meguiar’s Dual Action Polisher.

Tip: All the work should be carried out on cool paintwork and in a suitable work space.

All the techniques mentioned can be applied to any types of paint or gel coat. A halogen lamp will help show up any further defects. It is also important to remember to put the cable over your shoulder to prevent it dragging across the paintwork.